Brushless DC Pump

Home > Brushless DC Pump

Unique brushless dc pumps in the world: 1. Max head: 50m, Max flow: 6000L/hour. 2. Max head: 18m, Max flow: 16,800L/hour.

A brushless dc pump is a 12v or 24v mini bldc motor drive dc water pump that use magnetic force to rotate its impeller to pressurize and transport water for fluid lifting, booster, circulation system. It is a kind of typical mechatronic product.

A bldc water pump is a 12v 24v 5v 6v small water pump that use bldc magnetic motor to drive its impeller on its rotor in high speed to generate centrifugal force to lift, boost or circulate water, fuel or air. Thus, bldc water pump also named magnetic drive dc pump.

Due to its advantages in low price, small size, high-efficiency, long lifespan, safety, quiet, brushless dc water pumps are widely used as a fluid transport functional component in various equipment.

Standard Brushless DC Pumps by VOVYO:

Brushless DC Pump 12v

Max Head:0.7~1.5M Max Flow:2~3.4L/min

Brushless Submersible Water Pump VP30A

Max Head:1.5~3M Max Flow:2.5~4L/min

Brushless Water Pump(View 50 Models)

Head ≤50M Flow Range≤16800L/H

Brushless DC Pump 24v VP60A

Max Head:13~32M Max Flow:11~26L/min

Small High Pressure Pump VP60P

Max Head:13~32M Max Flow:11~26L/min

BLDC Pump VP60N

Head: 13M Flow:21L/min Noise≤ 45dB

Brushless DC Motor Pump

Max Head:4~6M Max Flow:12~15L/min

Brushless DC Water Pump VP40S

Max Head: 4~13M Max Flow: 5~13L/min

Small Solar Pump 12V

Max Head: 8~15M Flow: 10~13L/min

BLDC Food Grade Pump

Max Head:2~13M Max Flow:1.5~21L/min

Brushless Cooler Pump VP60D

Head: 2.4M Flow: 6L/min Noise≤ 24dB

Small Circulation Pump VP40T

Head: 4~15M Flow: 8~13L/min Noise≤ 45dB

High Pressure Water Pump VP60F

Max Head: 42M Max Flow: 19L/min

BLDC Aquarium Pump VP85A

Head: 3.5~5.5M Max Flow: 133~200L/min

BLDC Pump Motor VP40A

Max Head:≤13M Max Flow:≤1400L/H

Electric Water Pump Car VP90A

Max Head:24M Max Flow:10800L/H

Brushless Solar Water Pump

Head Range≤50M Flow Range:2~43L/min

BLDC Battery Powered Water Pump

Head≤50M Flow Range:2~40L/min

(VOVYO has strong brushless dc pump R&D capabilities. Unique pumps in the world: 1. 550W Single motor pump Max head: 48m, Max flow: 6000L/hour. 2. 120W Single motor pump Max head:32m, Max flow: 1500L/hour. We can OEM, ODM any performance brushless dc pump for you according to your special needs.)

Want to learn more?

Table of Contents

Brushless DC Pump Manufacturer

Brushless DC pump manufacturer VOVYO Technology Co., Ltd is a dc water pump supplier from China, which located in Dongguan city. The company is a R&D-oriented, high-tech enterprise that produces and sells brushless DC water pump, brushless solar water pump, brushless sumbersible water pump, brushless pool pump, automotive electric water pump, 110v, 220v, 380v AC revert to DC’s DC water pump. Is China’s mini brushless water pump research and development early, specification variety, industry positioning high-end dc pump brand enterprise.

The company brings together a group of domestic engineers who are engaged in the research and development of bldc water pump, 12v water pump, 24v brushless dc pump. At current, VOVYO has VP25, VP30, VP35, VP40, VP50, VP60, VP62, VP80, VP90, VP100, etc 10 series bldc water pumps. There are 5V, 6V , 12v, 24v, 48v and more than 1000 kinds of bldc motor water pumps are available.

VOVYO aslo has strong brushless DC pump’s OEM and ODM capabilities. We can customize various models brushless water pumps for users’ special size and appearance requirements, performance requirements, use environment requirements, voltage requirements, material requirements, and functional requirements.

VOVYO brand brushless DC pumps are not only widely used in the domestic market of China, but also exported to countries from Europe, America, East Asia, Southeast Asia, South America. It has good sales performance in the USA, India, Germany, Japan, UK, Australia, Canada, South Africa, Brazil, France, Italy, and other countries.

How Does a Brushless dc pump Work?

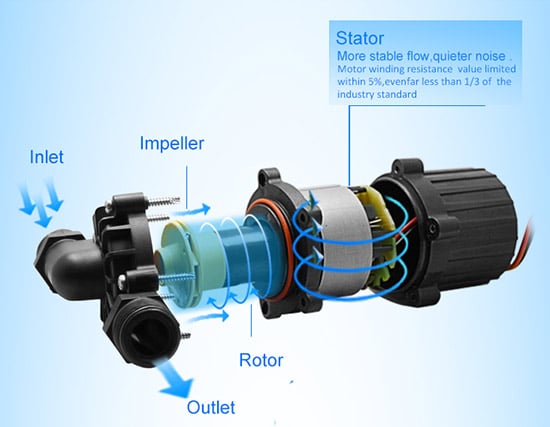

Brushless DC pump is driven by a brushless dc motor. The torque of the motor is the magnetic field generated by the coil on the silicon steel sheet (stator) to drive the permanent magnet (rotor) to work. The magnet is magnetized in n (n is an even number) stage, so that the magnet parts form a complete coupling magnetic system with each other. The magnetic force that produced by magnet drives the impeller on the magnetic rotor along with it to rotate at a high speed lead to liquid produces centrifugal force under the action of pressure energy and speed energy. Then under the action of centrifugation, the liquid stays along the blades until it is thrown out from the center to the surroundings, sent to the drain pipe through the pump casing, and transported to the working point.

Compared with the brush motor water pump, bldc pump does not need to use carbon brushes but through electronic commutation, hence it names brushless DC water pump.

Structure of Brushless DC Pump

Brushless DC pump (magnetic isolation pump) is mainly composed of the pump body (isolator), motor stator, shaft, bearing and rotor impeller etc.

1. Magnet (NdFeB permanent magnet)

Brushless DC pump stator is made of rare earth permanent magnet material, it has a wide operating temperature range (-45-400°C), high coercivity, and good anisotropy in the direction of the magnetic field. Demagnetization will not occur when the same poles are close. It is a good source of magnetic field.

2. Shaft

As brushless DC magnetic pump is driven by an energized coil to rotate the rotor to work. in order to maintain the rotor rotation smoothly and noise, people use high-performance ceramic shaft and sleeve with a high degree of accuracy to produce the pump, which effectively reducing the rotational resistance and noise.

3. Sliding bearing

The materials of bldc magnetic pump sliding bearings are engineering plastic plastic steel (POM) or ceramics. Since plastic steel (POM) and ceramics have good heat resistance, corrosion resistance and friction resistance. So the sliding bearings of magnetic pumps are mostly made of engineering ceramics. Since engineering ceramics are brittle and have a small expansion coefficient, the bearing clearance must not be too small to avoid shaft-holding accidents.

As the sliding bearing of magnetic pump is lubricated by the medium it conveys, different materials should be used to make the bearing according to different medium and working conditions.

4. Rotor

The magnet of the BLDC pump is injection molded with the impeller and form the rotor of the motor.

5. Impeller

The impeller of brushless DC water pump is generally made of PA66, PPE, PPS, etc. It is divided into open impeller, semi-open impeller and closed impeller. For the conveyed liquid temperature below 70 degrees Celsius, the impeller can be made of PA66 material, for the liquid temperature between 70~105, PPE material can be used, for the liquid temperature above 120 degrees Celsius, PPS or aluminum alloy materials should be used.

Brushless DC Pump VS Brushed DC Pump

As we all know, brushless DC pump is driven by a brushless DC magnetic motor, and the brushed DC pump is driven by a brush motor. Compared with brushed motors, brushless DC motors have many advantages, such as high efficiency, long life, low noise, etc., so brushless DC pumps are more advantageous than brushed DC pumps, mainly in the following aspects:

1. High waterproof performance

Due to its closed static seal, bldc motor water pump completely avoiding medium leakage, so it completely waterproof, therefore user can amphibiously use the pump. Also, the stator part and the rotor part of the magnetically isolated water pump are completely isolated, and the stator and circuit board parts are potted with epoxy resin, which is 100% waterproof.

2. High Working Efficiency

Brushless dc pump has more higher efficiency, so it can reach a same working performance with lower power consumption compared to a brushed dc pump. Also, brushless pump no need for independent lubrication and water cooling, thus reducing a lot of energy consumption.

3. Small vibration

Brushless DC water pump uses a magnetic motor to drive the rotor to rotate, which has a damping and vibration reduction effect, that lead to reduce the impact of the vibration of the brush motor on the pump. Also reduce the impact to the motor when the pump occurs cavitation vibration.

4. Low Working Noise Performance

Various required parameters can be adjusted through the winding of the stator, and you can operate it at a wide voltage. Also, the working noise of the bldc pump is lower than that of the DC brushed water pump with the same performance, which can reach 22dB or less.

5. Overload Protection

When the bldc water pump working in the condition of overload, its rotor will slip on the ceramic shaft, which protects the motor and pump. Moreover,the carbon brush powder of the brushed pump is easy to seep into the working fluid and pollute the circulating medium.

Which Pump is Better AC or DC?

There are mainly two types pumps in the water pump market, AC pump and DC pump. DC pumps are generally driven by DC motors or brushed motors powered by DC power lower than 36v voltage, while AC pumps are generally driven by AC motors higher than 36v voltage. Compared with AC pumps, DC pumps, especially the brushless dc pumps, have many advantages, such as:

1. Low Working Voltage More Safety

Most of the popular brushless DC pumps on the market have rated working voltages of 3.5v, 5v, 6v, 12v, 24v, which are all below the human safety voltage of 36v. Therefore, even if you are shocked by the pump at work, it do not harm to you. So, the safety of brushless water pumps are safer than most AC pumps that with a rated working voltage of 36v or more.

2. More Long Working Lifespan

Brushless DC water pump adopts electronic components for commutation, no need carbon brush commutation. Its rotor part uses permanent magnets material, and the water pump body uses environmentally friendly materials. Also it use high-performance wear-resistant precision steel shaft and sleeve which is integrated with the rotor through injection molding, by doing so avoid wear.Therefore, compared with AC Pump, the service life of the brushless DC pump is greatly enhanced.

3. Small Size and High Efficiency

Brushless DC water pump solves the problems of low speed and low head of the AC water pump. Generally speaking, the water head of the brushless water pump with the same volume can reach more than 3 to 10 times that of the AC pump.

4. Withstand High Temperature Working Fluid

Due to the high voltage of the AC water pump, the wire diameter of the stator coil winding is very thin and the number of turns is large, that will cause high internal heating of the product, which is not suitable for use in a high temperature environment. At present, the brushless pump can be customized to withstand the high temperature as high as 180 degrees. Therefore, brushless DC water pump can be made into an automotive electric water pump for using in automotive engine cooling and heat dissipation systems that require harsh heat resistance of the water pump.

5. Multiple functions, Wider Application Range

AC pumps do not have the control of the drive board, so they are not suitable for intelligent control occasions. However, we can customize various kind of control functions for DC pumps. Such as speed regulation, temperature difference control, and photosensitive control , reverse voltage protection, power Limitation, slipping protection, stall protection, over voltage protection, etc.

Are Submersible Pumps Brushless?

Submersible pumps can be divided into AC motor submersible pumps, brush DC motor submersible pumps, and brushless DC motor submersible water pumps according to the driving current form and the type of driving motor. Therefore, not all submersible pumps are brushless.

A brushless submersible water pump is a kind of 12v, 24v brushless DC permanent magnet motor driven water pump that can diving and work in water. As a new type of dc water pump with many advantages compared to AC water pump, brushed DC water pump, people widely use it in various kinds of equipment or systems that need to be used for diving, so it becoming a common submersible pump.

BLDC submersible water pump does not need input strong current, high voltage power supply, or even AC power, it can use low voltage DC power to directly drive the brushless DC motor in the pump housing. It has many advantages that are incomparable to AC pumps because they inherit the unique characteristics of brushless DC motors, mainly in the following aspects: 1. Safe and reliable, due to they work with less than 36V voltage which is safe to human. 2. Long working lifespan, because they are driven by brushless motors; 3. The stator and rotor are completely isolated, so it can be completely waterproof. 4. BLDC submersible water pump also has low noise, high efficiency, adjustable speed, multi-function, etc.

Therefore, with the widespread use of brushless water pumps, more and more submersible pumps are brushless.

How to Choose Brushless DC Pump?

At present, the brushless DC pumps on the market have different models, power, shape, materials, and functions. How to choose a more suitable bldc pump for your own products or applications such as water circulation and water booster systems is not very clear to many non-professional users. Now VOVYO will introduce you one by one:

1. Determine Rate Working Voltage

Users can determine the working voltage of the brushless dc water pump according to their own use occasions, product characteristics, power conditions, etc. At present, the rated working voltage of DC water pumps on the market is mainly 12V, 18V, 24V, 36V, 48V, etc. For special requirements, those that are not in the voltage parameter table can be customized by the manufacturer.

VOVYO company has developed 110V, 220V, 380V single-phase, three-phase AC input and that can supply for the brushless dc pump. There is conversion circuit inside the pump converts AC to DC and then drives the brushless DC motor inside the pump housing. With this technology it greatly improve the power and performance of this type of water pump, moreover, it can save users the trouble of matching DC power supply for the pump . User can select a voltage suitable for the power supply of the country’s ac power grid to supply power to the water pump according to the characteristics of the country’s mains.

2. Determine the Volume and Shape Requirements

Choose the form of the water inlet and outlet of the bldc motor water pump, the direction of the inlet and outlet, the size of the caliber, etc. Inlet and outlet mainly have the conventional straight form and threaded interface form, people generally use thread interface form for water heaters, hot water circulation pumps. The relative position of the inlet and outlet direction is 180 degrees horizontal or 90 degrees vertical to each other. Inlet and outlet caliber size 8mm, 10mm, 18mm, 20mm, the most commonly inlet and outlet diameter of thread form is 1/2″, 3/4″, etc.

3. Determine the Working Environment (Temperature, Medium)

Choose bldc water pump according to the temperature and fluid medium of the use environment. For the working environment of normal temperature, choose a pump with the highest working temperature around 60 degrees. For the working environment of hot water circulation such as water heater, choose a pump with the highest working temperature between 70~100 degrees. For the working environment of high temperature in all kinds of cars, you can choose a pump with the highest temperature resistance of 120 degrees. For some pumps used for cooling fuel cell heat dissipation, you need to use a pump with temperature resistance of 180 degrees water pump. You need to choose a brushless water pump with food grade material, if the working liquid medium is quoted water, juice, beverage, etc.

4. Determine Functional requirements

Determine the functional requirements such as idle protection, jamming protection, speed control, temperature and humidity control, timing control, music control, voice control, feedback control, flow control, and other pump-related control systems.

5. Determine the Required Flow and Pressure Requirements of The System

For example, at the end of the circulating system needs to come out after the circulation of water for 5L/Min, then need to subtract the system damping and pressure head loss to produce 5L/Min flow. For example, the system circulation height is 2M, the system damping and along the loss of 1M, the total required pressure head is 3M. If there is a sudden reducer in the system (for example, the system originally pump outlet inside diameter 15MM, the system pipeline in the smallest inside diameter only 5MM, or the system has a heat dissipation row, heat dissipation hole, U-shaped pipe, etc.). It is necessary to increase the pressure head loss to compensate for the loss of the reducer for water flow.

A Case Study on Choosing Brushless DC Pump

A case for example: Select a appropriate brushless DC water pump for a desktop fountain product. Its supply voltage is 24V, system height is 1M, system damping head loss is 1M, and flow rate requirement is 5L/Min.

System piping flow rate requirement is close to the pump flow rate selection method:

First of all check the parameters in the selection table of all models, lock the pumps with parameters above 5L/Min. Check the VOVYO Pump’s selection table, we can know except for VP30A series, all other pump models can reach this requirement of 5L/Min.

Second check the summary table of the head curve chart of the brushless dc pump, and study which curve intersects with the straight line of head 2M falling near 5L/min. For example, for the VP40F series pump in figure 1, there are 4 curves intersecting the vertical coordinate 2M, corresponding to the horizontal coordinates 3.5L/Min, 6L/Min, 7.5L/Min, 9L/Min. Among which the closest is 6L/min, corresponding to the curve VP40F-1240, 12 means 12V, 40 means 4M. But now we need a 24V pump, so the closest one is VP40F-2450. However, the parameter is 7.5L/Min. In this case, we can ask VOVYO to adjust the parameter at the time of production, and adjust the parameter lower to reach the requirement of 5L/Min.(VOVYO can adjust the power to any more smaller one at the time of production for all models, and the parameter of the pump is adjustable.)

The selection method when the diameter of the system pipeline and the diameter of the water pump outlet are very different:

If the difference between the minimum internal diameter of the system and the internal diameter of the pump outlet is large, it is necessary to compensate for the flow loss of the pump by increasing the pressure head loss.

For example, if the minimum internal diameter of the system is only 5mm and the internal hole of the pump is 9mm, it is necessary to increase the reducer pressure head loss of maybe 2M when selecting the pump. The total pressure head loss when selecting the pump is 4M (height 1M, damping 1M, reducer pressure head loss 2M), need to reach 5L/Min, check Figure 1 in the 4M horizontal line and 4 curve intersection point only with the VP40F-2460 curve intersection point corresponding to the constant coordinate is 5L/Min, so the need to choose is the VP40F-2460 model. (The specific pressure head loss needs to be communicated with the professional persons.)

How to Use Brushless DC Pump?

Correctly mastering the use method of brushless dc water pumps is an important factor in extending the life span of the pump and saving economic losses. So how to use a brushless dc pump? You can following the below methods:

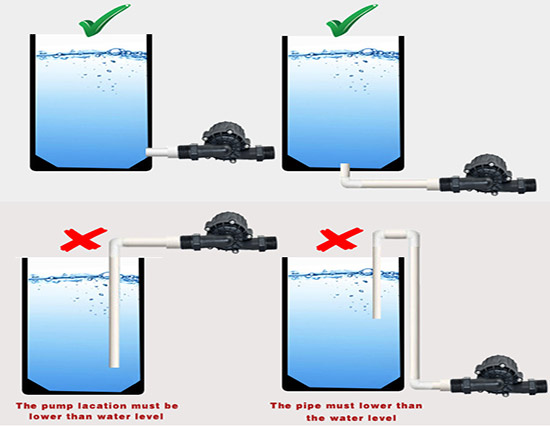

1. Installation Method

Brushless DC pump is a centrifugal pump, so, it cannot automatically discharge air, and must be submerged or installed below the liquid surface when in use. (Water can automatically flow in when the pump is not working.) The installation method is as follows:

2. Do Not Idle Run The Pump

You should not idle run the brushless pump, because there is no medium lubrication when idling, so it is easy to wear, easy to heat up resulting in jamming. Therefore, you can customize idle protection, jamming protection to protect the pump motor.

3. No Ferromagnetic Impurities, Particles Are Allowed in The Working Liquid

You should try to do a good job of filter, when conveying media containing solid particles it should be filtered at the entrance of the bldc water pump flow pipe to prevent impurities from entering the pump jammed. Do not allow ferromagnetic impurities and particles to enter the magnetic drive and bearing. Flush in time after conveying media that are easy to crystallize or precipitate (fill the pump cavity with clean water after stopping the pump, and discharge cleanly after 1min operation) to protect the service life of the sliding bearing.

4. Operate the Pump Within the Allowed Voltage Range

You should use the bldc pump within it’s rated voltage, otherwise it will burn the motor. You should choose a pump with more higher rated voltage, if there are over-voltage or other functional requirements.

5. Prevent Demagnetization

You should operate the brushless dc pump under the specified temperature conditions, and the temperature of the medium is strictly prohibited to exceed the limit. You can install a platinum resistance temperature sensor on the outer surface of the magnetic pump isolation sleeve to detect the temperature rise in the ring gap area, in order to alarm or shut down when the temperature exceeds the limit.

What Are the Common Faults of Brushless DC Pump and How to Repair?

As brushless dc pump has many advantages such as small in size, long working lifespan, safe, it is loved by the market and is widely used in various industries. However, some users feedback that their bldc pump some times does not work normally. The causes and repair methods of common failures are now introduced as follows:

1. Pump Motor Does Not Turn

Check the power lines and wiring of the pump, repair the broken wire or repair the poor contact.

2. Pump Does Not Turn With a Humming Sound

You should check whether the power supply power is too small (power supply power should be ≥ 1.5 times the power of the pump), check whether the pump rotor is clogged with dirt; Brushless dc pump work but can not pump water: it caused by the pump cavity with air or air in the water pipe; Solution: Exhaust, repeatedly start stop the bldc water pump more than 3 times and keep the pump working a few minutes after it can normally pump water.

3. Water Pump Work But Can Not Reach The Proper Flow

Impeller damage, speed is not enough, head is too high, there are debris blocked in the pipe, etc. There is air in the pump cavity or air in the water pipe, the bldc water pump will be repeatedly started and stopped more than 3 times; Water head is not enough, causes of this failure are: air in the transport medium, impeller damage, speed is not enough, the specific gravity of the transported liquid is too large, the flow is too large. Abnormal sound happens when the pump is running: there may be foreign matter in the pump cavity, then clean the pump cavity. The pump motor is hot: You should check whether the pump rotor is blocked, whether the power supply is normal, whether the brushless dc pump motor is burned out due to water leakage.

4. High Vibrating Sound

When place the bldc pump on the hawking surface or on the board with rated working voltage, there is great vibration and noise, and if the working pump is held in the hand or put into the water, the hand feels vibration but no noise. It means that the rotor may be eccentric, the shaft hole becomes bigger or the blade is damaged and deformed. Solution: for slight vibration and noise, add anti-vibration soft body cotton or sponge gasket anti-vibration. For serious vibration and larger noise, replace a new rotor.

5. Loud working noise

Check whether there are foreign objects in the pump cavity, whether the rotor and shaft are normal, whether the gasket, shaft, front cover and pump body are intact, whether the power supply voltage is normal.

6. Water leakage

Poor assembly of the pump casing and leakage of the seal. Solution: You should Re-tighten the screws or replace the failure sealing ring with a new one to completely solve the problem of water leakage of brushless dc pump.

Frequently Asked Questions About Brushless DC Pump

What is a Brushless Pump?

Brushless pump is a small water pump that built by a brushless motor, it use centrifugal force that generated by the impeller that rotate in high speed to lift, booster or transfer water, coolant, fuel ,air etc.

How Long Can a DC Pump Run Continuously?

As we all know DC pumps are divided into brushed dc pump and brushless dc pump, so there are much difference in the working lifespan of different type dc pumps.

Generally speaking, a dc pump that built by a brushed motor can continuously run for 2000~4000 hours. However a dc pump that built by a brushless dc motor can continuously run for 24 hours per day for more than 30,000 hours, some of them even can continuously runs 50,000~60,000 hours.

What is BLDC Motor Pump?

As the name suggests, a bldc motor pump is a small water pump that built by a bldc motor. It usually used to pressurize, circulate, or pump water for various product or different uses and applications. The bldc motor pump can have a rating of 3V, 5V, 6V, 12V, 24V, 48V and you always can power it using a dc power supply, battery or solar panel.

PRODUCT CATEGORY

FEATURED PRODUCTS

| Rated Voltage | 24V |

| Max Head | 24Meters, 25Meters |

| Max Flow | 100L/Min, 110L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 183x103x240mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 45 Meters |

| Max Flow | 100L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 175x100x170mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 18M |

| Max Flow | 280L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 188.1x100x176.9mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 13.5V, 24V |

| Max Head | 14M |

| Max Flow | 55L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 131x112x80mm |

| Noise | ~48dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 220V |

| Max Head | 38M, 48M |

| Max Flow | 100L/Min,100L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 223.4×126.0x178.0mm |

| Noise | ~50dB |

| Liquid Temperature | -30~70 Celsius |

| Rated Voltage | 6V, 12V |

| Max Head | 1.5 Meters, 3 Meters |

| Max Flow | 2.5L/Min, 4L/Min |

| Inlet Diameter | Φ8mm |

| Outlet Diameter | Φ8mm |

| Dimensions | 53.5x40x34mm |

| Noise | ~30dB |

| Liquid Temperature | -25~50 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ18mm |

| Outlet Diameter | Φ9.8mm |

| Dimensions | 82.45×48.0x67.6mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 3M, 8M |

| Max Flow | 8L/Min, 13L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 82.3x102x46.4mm |

| Noise | ~40dB |

| Liquid Temperature | -40~110 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 83.4x48x69.7mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 8M, 15M |

| Max Flow | 20L/Min, 25L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 96.9x73x84.3mm |

| Noise | ~40dB |

| Liquid Temperature | -20~100 Celsius |

| Rated Voltage | 12V, 24V,24V,24V |

| Max Head | 11M, 20M, 25M, 32M |

| Max Flow | 20L/Min, 24L/Min, 25L/Min, 26L/Min |

| Inlet Diameter | Φ20.3mm |

| Outlet Diameter | Φ11.3mm |

| Dimensions | 90.9x60x85.85mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

FEATURES CATEGORY

SUPPORT & BLOG

Get Product Catalog

16.5Mb PDF File, Covers 200+ Models Products.