DC Water Pump

Home > DC Water Pump

Unique dc water pumps in the world: 1. Max head: 50m, Max flow: 6000L/hour. 2. Max head: 18m, Max flow: 16800L/hour.

A DC water pump is a small electric water pump motor that can be supplied by a 24v, 12v, 5v, 6v batteries, solar panels, or other DC power supplies. It utilizes centrifugal force to move, pressurize, or circulate water and other liquids.

Unlike AC water pumps, which are powered by higher voltage AC motors (120V, 220V, 240V, 380V), DC water pumps offer several benefits, including affordability, safety, energy efficiency, quiet operation, and portability. Due to their low voltage operation, DC water pumps are ideal for applications where safety, low noise, and minimal power consumption are essential. As a low voltage electric water pump, dc pumps are commonly used in various settings, such as household appliances, vehicles, pools, wells, pet water fountains, aquariums, fish tanks, decorative fountains, water heaters, water circulation systems, and automotive cooling systems.

Standard DC Water Pumps by VOVYO:

DC Fountain Pump VP30

Max Head:0.7~1.5M Max Flow:2~3.4L/min

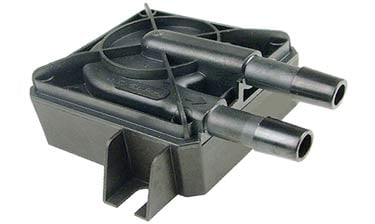

DC Submersible Pump VP30A

Max Head:1.5~3M Max Flow:2.5~4L/min

12V DC Water Pump (View 50 Models)

Head Range≤50M Flow Range≤16800L/H

DC Transfer Pump VP40F

Max Head:4~6M Max Flow:12~15L/min

Hot Water Pump VP40T

Max Head: 8~15M Max Flow: 10~13L/min

Submersible Water Pump VP40H

Max Head: 8~15M Flow: 10~13L/min

DC Food Grade Pump VP35C

Max Head:1.5~3M Max Flow:4.5~7L/min

DC Cooler Pump VP60D

Head: 2.4M Flow: 6L/min Noise≤ 24dB

DC Booster Pump VP40S

Head: 8M Flow: 13L/min Noise≤ 40dB

DC High Pressure Water Pump VP60F

Max Head: 42M Max Flow: 19L/min

DC Aquarium Pump VP85A

Max Head: 3.5~5.5M Max Flow: 133~200L/min

24V DC Water Pump (View 10 Models)

Max Head:≤32M Max Flow:≤1400L/H

DC Electric Water Pump VP80E

Max Head:10~14M Max Flow:50~58L/min

Battery Powered DC Pump

Head Range≤1~50M Flow Range:2~40L/min

Want to learn more?

Table of Contents

DC Water Pump Manufacturer

VOVYO Technology Co., Ltd is a leading DC water pump manufacturer based in Dongguan, China. The company specializes in the research, development, and production of a wide range of small water pumps, including circulation pumps, automotive electric water pumps, food-grade pumps, quiet pumps, booster pumps, and water heater pumps. With over a decade of experience, VOVYO has successfully developed 9 pump series, ranging from VP25 to VP90, all powered by 12V, 24V, 5V, or 6V BLDC motors. These pumps are widely used in applications such as small water circulation systems, pet water fountains, irrigation, electric water heaters, water booster systems, coffee machines, auto engine cooling, motor controller cooling, and automotive heat management systems.

VOVYO’s DC pumps have gained global recognition and are exported to numerous countries worldwide, including the United States, India, Japan, England, Germany, Australia, Canada, Italy, South Korea, Brazil, France, and South Africa. The brand is known for its high-quality, reliable, and efficient water pump solutions.

How Does a DC Water Pump Work?

Common mini water pumps include Brushed DC pump, Brushless motor DC pump, Brushless DC pump, etc. What are their working principles? The following is a detailed explanation:

1. Brushed DC Water Pump

A brushed DC water pump operates using a brushed motor. In this design, the direction of the current in the coil changes alternately, achieved through a commutator and brushes that rotate with the motor. However, as the motor runs, the carbon brushes gradually wear down. Over time, as the pump operates for hundreds of hours, the wear on the carbon brushes increases, leading to louder noise. Eventually, the carbon brushes wear out completely and can no longer facilitate commutation. As a result, brushed DC pumps have a shorter lifespan, produce more noise, generate electromagnetic interference, and have poor air-tightness, making them unsuitable for submersible applications. Despite these drawbacks, they are cost-effective and affordable.

2. Brushless Motor DC Water Pump

Brushless motor DC water pump is a pump use its dc motor to drive its impeller that connect the motor shaft to work. There is a gap between the stator and the rotor of the water pump. If you use it for a long time, water will penetrate into the motor and increase the possibility of motor burnout. It suitable for mass production, and with relatively low production cost.

3. Brushless DC Water Pump

Brushless DC pump utilizes Hall sensors, microcontrollers, or software programs to manage current commutation. Unlike brushed motors, it eliminates the need for carbon brushes, thereby avoiding the wear and tear that shortens motor life. This design significantly extends the pump’s lifespan. Additionally, the stator and rotor are magnetically isolated, and the stator and circuit board are fully encapsulated in epoxy resin, making the pump 100% waterproof.

The rotor in a brushless DC pump is constructed from permanent magnets, and the pump body is made from eco-friendly materials, ensuring stable performance. Parameters such as speed can be adjusted by modifying the stator windings, and the pump can operate across a wide voltage range. Brushless DC pumps are known for their ability to work underwater, long operational life, high efficiency, low noise levels, and compact size.

What Types of DC Water Pump Are There?

With the rapid growth of home appliance and precision instrument industries, compact, oil-free, and eco-friendly DC-powered pumps have gained widespread adoption. The majority of miniature water pumps utilize DC power systems, featuring an integrated motor-pump design where the DC motor directly powers the pump mechanism. These devices are commonly referred to as DC micro water pumps due to their direct current operation.

DC pumps vary significantly in technical specifications, particularly when classified according to their rated DC voltage requirements. This classification system helps differentiate models based on the electrical parameters needed to drive their integrated motors effectively.

1. 12V DC Pump

A 12V DC water pump is an electric water pump driven by a 12V DC motor. You can pair it with a switching DC stabilized power supply for voltage transformation or connect it directly to a car battery, making it highly convenient for various uses. People commonly employ these pumps in areas like water treatment, environmental protection, medical applications, industrial control, scientific research labs, water circulation, cooling, lifting, transfer, pressurization, spraying, and transportation.

2. 24V DC Pump

A 24V DC water pump is a compact water pump that operates on a 24V DC power source. Depending on the driving mechanism, it comes in two types: 24V brush water pumps and 24V brushless DC pumps. These pumps find extensive use in household appliances, automotive applications, handicrafts, solar energy systems, household items, electrical devices, and the food industry.

3. 5V DC Pump

A 5V DC water pump is a miniature pump that runs on a 5V DC power supply, which can come from a battery, solar panel, or USB source. People primarily use it in applications like fish tanks, cat water fountains, and desktop fountains

4. 6V DC Pump

A 6V DC water pump is a micro pump powered by a 6V DC supply. It suits applications that demand small size, low noise, and minimal power consumption.

DC Water Pump VS AC Water Pump

DC water pump is a electric water pump driven by a DC motor. AC water pump is driven by an AC motor. Why do people more prefer to use DC pumps powered by 12v, 24v, 5v, 6v instead of ac water pump powered by 120v, 220v, 240v, and 380v in many applications? If you don’t know the advantages of the dc pump when compared with ac water pump which lead to people more prefer dc electric water pump, you can find the answer from the following content:

There are 4 Major Disadvantages of AC Water Pump

1. Safety Concerns

People generally recognize 36V as the safe voltage threshold for the human body. However, AC pumps operate on power supplies exceeding 120V and require extremely high insulation standards. If the wiring sustains damage, the system can easily cause electric shock accidents. When used in fish tanks, leakage currents may endanger aquatic life, leaving no reliable safety safeguards.

2. Short Operational Lifespan

AC pump motors typically use aluminum-clad copper wire cores, which generate operating temperatures exceeding 120°C. These high temperatures significantly shorten the motor’s lifespan. Even with equivalent performance parameters, AC pumps consume far more energy than DC alternatives.

3. Excessive Noise Levels

Manufacturers often exaggerate performance metrics, leading to widespread quality inconsistencies among AC pumps. Users frequently encounter mismatches between advertised specifications and actual performance.

4. Inconsistent Product Standards

The quality of AC water pumps on the market is uneven, and pump’s parameters are generally false in the process of using.

There are 4 Major Advantages of DC Water Pump

1. High Safety

DC water pumps operate at 5V-24V, well below the 36V human safety threshold. This design eliminates electric shock risks even if wiring fails. For unstable power grids, built-in transformers or adapters stabilize voltage inputs, ensuring continuous operation. Battery backups further guarantee functionality during outages.

2. Extended Durability

Premium DC pumps incorporate pure copper motors and brushless DC technology, achieving operational lifespans exceeding 30,000 hours. Advanced thermal management maintains stable low-temperature operation, preventing performance degradation over time.

3. Quiet Operation

Innovative vibration-dampening designs and flexible suction cup mounts reduce operational noise below 40dB. This silent performance remains consistent throughout the pump’s lifecycle.

4. High Performance

DC pumps outperform AC models in energy efficiency and power density. All specifications undergo rigorous testing to ensure accuracy, with diverse models tailored for specific flow/pressure requirements while minimizing power consumption.

How to Choose a DC Water Pump?

The market offers a wide variety of DC pumps, but not all will suit your specific needs. This is due to differences in working voltages, sizes, inlet and outlet configurations, performance levels, and environmental conditions among pumps.

When selecting a DC pump for your application, consider the following factors to ensure you choose the most suitable and cost-effective small DC water pump.

1. Working Voltage

DC pumps come in various voltage ratings such as 3V, 5V, 6V, 12V, 24V, and 48V. Generally, lower voltage pumps have smaller performance capabilities. For pet water pumps or desktop fountain pumps, opt for a 3~6V rated pump. For coffee machines, drinking fountains, or food-grade applications, a 12V DC pump is advisable. For vehicles or motorcycles, consider a 12V or 24V electric water pump.

2. Water Head

The maximum head of a DC pump typically refers to the static head without water flow when pumping to the maximum height. To pump water to a certain height while maintaining flow, ensure the required head exceeds the specified pumping height. It’s generally recommended to add a 5%~10% margin to the water head when selecting a model.

3. Water Flow

Flow rate is a critical performance metric for selecting a water pump, directly impacting the pumping efficiency of the system. When choosing a DC pump, base your decision on the maximum flow rate, considering the normal flow rate as well. If the maximum flow rate is unknown, assume it to be 1.1 times the normal flow rate.

4. Working Environment

For environments requiring submersion, such as aquariums and fish tanks, select a DC submersible pump. For high-temperature environments like solar water heaters, car engine cooling, or electric vehicle battery cooling, choose a DC pump capable of withstanding high temperatures. For instance, a solar water heater requires a pump with a maximum operating temperature of 100°C, while a fuel cell cooling system in a new energy vehicle might need a pump that can endure up to 180°C.

5. Dimensions, Shape of Water Inlet and Outlet

Ensure the DC water pump you choose fits the external dimensions of your appliance, equipment, or water circulation system. This ensures it can be installed in the designated space. For compact spaces, consider a brushless DC pump, which offers higher efficiency and a smaller footprint compared to brushed DC pumps with similar performance. Also, match the inlet and outlet directions and shapes with your piping system. For example, water heaters typically require a 24V or 12v inline water pump with 1/2″ or 3/4″ threaded inlets and outlets.

Can a DC pump Run on AC?

You might realize after purchasing a DC pump that you don’t have a DC power supply available, only an AC supply. Additionally, you may not want to spend extra money on a DC power supply. This situation often leads to the question: Can I use an AC power supply to run the DC pump? Many users, including our customers, frequently ask this question.

So, can a DC pump run on AC power? The straightforward answer is NO. Let me explain this in detail:

A DC pump cannot operate on AC power because of the following reason: While a single-phase series-excited DC motor can connect to an AC power supply, as it works with both AC and DC power, the DC motor used in a DC pump is not a single-phase series-excited type. This means it cannot connect to an AC power supply. As a result, you must use direct current to power a DC water pump.

If you still want to use AC power to run the DC pump, the best solution is to use a filter rectifier. This device will convert the AC power into a stable direct current, which can then safely power the DC water pump. Attempting to run a DC pump directly on AC power without conversion will likely burn out and damage the pump.

How to Choose DC Power Supply for DC Water Pump

Many users struggle to choose the best DC power supply for their water pumps due to the wide variety of models available. Below, we’ll guide you through key factors to consider:

1. Matching Power Supply Types

Check your DC water pump’s rated voltage first. For pumps rated at 48V, 24V, or 12V, a standard DC power adapter or battery will work. For lower voltages like 9V, 6V, 5V, or 3V, consider alternatives such as solar panels, dry batteries, chargers, or even a computer’s USB port. For example, a 12V pump can run on a compatible adapter or battery, while a 3V pump might pair well with a USB power source. USB interface to power the battery powered water pump.

2. Prioritize Voltage Regulation

Always pair your DC water pump with a regulated switching power supply. A stable voltage under varying loads ensures consistent performance. Unregulated power supplies may show high voltage when idle but experience sharp drops when connected to the pump. This instability can disrupt the pump’s operation, especially if pipeline loads change during use.

Avoid using resistors to step down voltage, as fluctuating pump currents (caused by load changes) will alter the resistor’s voltage division. While regulated and unregulated power supplies have minimal price differences, always opt for the regulated version for reliability.

Common Pitfall: Some users try powering pumps with AC lighting transformers (e.g., 220V AC to 12V AC converters). These lack the filtering and voltage stabilization of DC switching power supplies, making them unsuitable for pumps.

3. Ensure Adequate Power Capacity

Choose a DC power supply with an output current rating higher than your pump’s maximum operating current. This guarantees sufficient energy delivery. Avoid overly cheap switching power supplies, as sellers often exaggerate their specifications to attract buyers.

Consequences of an undersized power supply:

- Pump fails to start.

- Pump stalls under load after initial operation.

- Reduced performance during use.

By prioritizing voltage regulation, proper capacity, and compatibility, you’ll ensure smooth, efficient operation for your DC water pump system.

What Should I Pay Attention to When Buying or equipping a DC Power Supply for DC Water Pump?

The market offers a wide variety of DC power supplies, but their quality can vary significantly. When selecting or equipping a DC power supply for a DC water pump, keep the following points in mind:

1. Electrical Control Components

You should avoid using electrical control components, such as integrated blocks, to directly power the DC pump. Doing so may lead to insufficient power supply.

2. Output Current

If you use a switching power supply with a low-rated output current to power a mini high-pressure DC water pump with a high-rated current, the pump may stop running immediately after starting. This issue is not due to a pump malfunction but rather because the power supply cannot deliver enough current. To resolve this, replace the power supply with one that has a higher-rated output current.

3. Quality of DC Power Supply

When testing power supplies with the same voltage and output power but different prices, you may notice that a high-priced power supply can easily drive the pump, while a low-priced one may dim its power light, trigger current protection, and cause the pump to stop. This highlights the importance of verifying the reliability of the power supply and checking for false parameters on the nameplate.

4. Inrush Current

The load current parameters listed on the pump nameplate typically do not account for the starting inrush current. When purchasing a power supply, you should ensure it can handle the inrush current. A good rule of thumb is to choose a power supply that can provide at least 1.5 times the pump’s maximum load current.

How to Use DC Water Pump?

DC water pumps are popular due to their compact size, lightweight design, safety, reliability, and high efficiency. To ensure the pump operates efficiently and lasts longer, follow these guidelines:

1. Use DC Power Supply

Always power the DC water pump with a DC power supply. Using an AC power source can damage the motor.

2. Operate Pump Within Its Rated Voltage

Always use the pump within its rated voltage range. If you need higher voltage, choose a pump with a corresponding rated voltage. For example, do not use a 24V power supply for a pump rated at 12V, as this can burn out the pump.

3. Ambient Temperature and Working Fluid Temperature

DC motors come in two-phase and three-phase types. Two-phase motors have limited heat dissipation and are suitable for working fluids below 60°C. If the environment or fluid temperature exceeds 60°C, opt for a pump with a three-phase motor to avoid motor damage.

4. Avoid Frequent Switching

Do not switch the DC pump on and off repeatedly. When the pump stops, a back-current occurs. Restarting it immediately can cause excessive starting current, leading to winding burnout. Frequent starts can also damage the motor windings due to the high current required during startup.

5. Keep the Pump Chamber Full of Water

As we all know, DC water pumps are centrifugal and cannot automatically expel air. To prevent dry running and motor damage, always submerge the pump or install it below the liquid level to ensure the pump chamber remains filled with liquid.

6. Avoid Idling

Do not run the pump without liquid, as this lack of lubrication can wear down the shaft and bearings. Prolonged idling can even burn out the pump.

7. Avoid Pumping Liquids with Large Impurities

DC water pumps are designed for clean water and cannot handle large impurity particles. Prevent hard particles from entering the pump, and avoid using it in water with large impurities. Otherwise, the shaft may wear out quickly, leading to pump failure or motor burnout.

By following these tips, you can ensure the longevity and optimal performance of your DC water pump.

What Are the Common Faults of DC Pump and How to Repair?

DC pumps have gained popularity worldwide due to their low working voltage, safety, reliability, compact size, lightweight, and affordability. They find extensive use in various industries, including industrial applications, home appliances, aquariums, car cooling systems, and fountains. However, users may encounter some issues while operating DC pumps. Here’s a detailed guide on how to address these problems:

1. Pump Fails to Operate

When you connect the DC pump to the power supply and turn it on, the motor doesn’t work, and the pump fails to move water.

Possible causes:

The power cord connector may not be securely attached to the battery terminal, or the wire connection might be loose, cutting off power to the motor.

The DC stabilized power supply might be faulty.

The battery could be low on power.

Poor contact between the motor and the carbon brush might prevent the pump from starting.

If the pump has been unused for a long time, the impeller might have rusted, making it unable to rotate.

Solution:

Ensure the power cord connector is firmly connected to the battery terminal. If the impeller is rusty, clean it to allow smooth rotation and restore the pump’s functionality.

2. Pump Fails to Pump Water

After starting the motor, the pump heats up, hums, but doesn’t pump water. In such cases, stop the pump immediately.

Cause:

The pump chamber may not have enough water, causing the pump to run dry and fail to function properly.

Solution:

Add enough water to the pump chamber, ensuring the water level rises above the impeller’s axis. Avoid overfilling the chamber.

3. Low Water Output

The motor starts, but the pump produces a low and uneven water flow.

Cause:

The impeller might be damaged or worn out, or the suction pipe could be leaking.

Solution:

Repair or replace the seal, install a new impeller, and fix any leaks in the pipeline.

4. Intermittent Water Flow

During operation, the pump suddenly makes a muffled noise, and the water flow becomes irregular.

Cause:

Debris might be blocking the filter or suction pipe, hindering water intake. Alternatively, debris inside the pump could be preventing the impeller from functioning properly.

Solution:

Clear any debris blocking the filter and suction pipe. If necessary, open the pump cover and remove any debris inside to restore normal impeller operation.

5. Pump Stops Suddenly

While running, the motor stops abruptly, and the pump ceases to pump water.

Cause:

Solid debris, such as hard sand, might have entered the pump and jammed the impeller. Alternatively, the battery might be low on power.

Solution:

Remove any debris from the pump to free the impeller. If the battery is low, recharge it fully.

Advanced Functions of DC Water Pump

Have you ever faced issues like burning out the pump due to reversing the power supply polarity? Or using the pump in water with large impurities, leading to blockages and damage? Perhaps you’ve wished for adjustable flow rates to suit different needs. To avoid such problems and prevent losses caused by improper operation, VOVYO recommends using DC pumps with advanced protection features.

Here are some advanced functions that modern DC pumps offer:

1. Reverse Polarity Protection

As we all know, reverse connection will cause a large current to break down the dc water pump controller and damage the water pump. So, to protect it, a water pump should have reverse connection protection function. That is, the circuit protection triggered when the positive pole of the input power supply of the dc water pump and the negative pole of the power supply are reversely connected, and stop the pump working.

2. Locked-rotor Protection

If the pump faces excessive load or mechanical jamming during startup or operation, this feature triggers circuit protection to prevent burnout.

3. Idling Protection

This function activates when the pump runs without a load or with a very light load, preventing damage.

4. Over Voltage protection

When the input voltage exceeds the pump’s normal operating range, this feature shuts off the controller to protect the motor and other components.

5. Over Temperature Protection

If the dc water pump’s controller overheats due to high ambient temperatures or excessive power consumption, this function activates to prevent damage.

6. Speed Adjust Function

This feature allows you to adjust the pump’s rotor speed. You can achieve this by either changing the input voltage or using a PWM power supply with adjustable duty cycles.

7. FG Signal Function

The FG (Frequency Generator) signal provides real-time feedback on the motor’s speed. By analyzing the pulse signals from the FG wire, the control system can monitor the pump’s operating status, such as flow rate and whether the pump has stopped unexpectedly.

8. Constant Power Function

This feature ensures the motor doesn’t overpower. It allows the pump to deliver high flow rates at low pressure and reduced flow rates at high pressure. A DC constant pressure pump can even achieve zero flow and pressure when needed.

By choosing a DC pump with these advanced features, you can enhance its durability, efficiency, and adaptability to various working conditions.

PRODUCT CATEGORY

FEATURED PRODUCTS

| Rated Voltage | 24V |

| Max Head | 24Meters, 25Meters |

| Max Flow | 100L/Min, 110L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 183x103x240mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 45 Meters |

| Max Flow | 100L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 175x100x170mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 18M |

| Max Flow | 280L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 188.1x100x176.9mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 13.5V, 24V |

| Max Head | 14M |

| Max Flow | 55L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 131x112x80mm |

| Noise | ~48dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 220V |

| Max Head | 38M, 48M |

| Max Flow | 100L/Min,100L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 223.4×126.0x178.0mm |

| Noise | ~50dB |

| Liquid Temperature | -30~70 Celsius |

| Rated Voltage | 6V, 12V |

| Max Head | 1.5 Meters, 3 Meters |

| Max Flow | 2.5L/Min, 4L/Min |

| Inlet Diameter | Φ8mm |

| Outlet Diameter | Φ8mm |

| Dimensions | 53.5x40x34mm |

| Noise | ~30dB |

| Liquid Temperature | -25~50 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ18mm |

| Outlet Diameter | Φ9.8mm |

| Dimensions | 82.45×48.0x67.6mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 3M, 8M |

| Max Flow | 8L/Min, 13L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 82.3x102x46.4mm |

| Noise | ~40dB |

| Liquid Temperature | -40~110 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 83.4x48x69.7mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 8M, 15M |

| Max Flow | 20L/Min, 25L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 96.9x73x84.3mm |

| Noise | ~40dB |

| Liquid Temperature | -20~100 Celsius |

| Rated Voltage | 12V, 24V,24V,24V |

| Max Head | 11M, 20M, 25M, 32M |

| Max Flow | 20L/Min, 24L/Min, 25L/Min, 26L/Min |

| Inlet Diameter | Φ20.3mm |

| Outlet Diameter | Φ11.3mm |

| Dimensions | 90.9x60x85.85mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

FEATURES CATEGORY

SUPPORT & BLOG

Get Product Catalog

16.5Mb PDF File, Covers 200+ Models Products.