Mini Water Pump

Home > Mini Water Pump

A mini water pump is a 3v, 5v, 6v, 12v, 24v dc water pump motor or 110v, 220v, 240v ac water pump that use centrifugal force to trsanfer, boost or circulate water for various water application systems or machines. It also named miniature water pump, tiny water pump.

A small water pump is a 24v, 12v dc motor water pump or 120v, 230v, 240v, 380v ac water pump that plays the role of trsanfer, lift or pressurize water, fuel, coolant in various water circluation, booster systems. Include small submersible water pump, small solar water pump, etc.

Mini water pumps are widely used for applications that requires use pump with small volume, low power consumption and low price. Such as applications for: Aquarium, fish tank, cat water fountain, solar water fountain, water cooling system, water booster, water heater, water circulation system, car wash, agriculture, medical industries and home appliance etc.

Standard Mini Water Pumps by VOVYO:

Mini Fountain Pump VP30

Mini Fountain Pump VP30 is a small water pump. People widely use it for fish tank, solar fountain, tabletop fountains, pet water fountain, etc. Max Head:0.7~1.5M Max Flow:2~3.4L/min

Mini Motor Pump VP30A

Mini Motor Pump VP30A driven by 5v, 6v, 12V DC motor. It commonly used in desktop crafts, medical equipment, soilless cultivation, aquarium tanks, etc. Max Head:1.5~3M Max Flow:2.5~4L/min

Small Water Pump (View 50 Models)

Small Water Pump are usually used in water pumping system, air conditioning water circulation system, domestic water circulation system, etc. Head Range≤50M Flow Range≤10800L/H

Small Circulation Pump VP40T

Head: 8~15M Max Flow: 10~13L/min

Small submersible Pump VP40F

Max Head: 5M Max Flow: 16.6/min

Small High Pressure Pump VP60P

Head: 8~32M Flow: 17~26L/min Noise≤ 45dB

Small Water Pump 24V

Max Head:4~6M Max Flow:12~15L/min

Small Booster Pump VP40S

Max Head: 3~8M Max Flow: 8~13L/min

Small Solar Pump 12V

Head: 8~15M Max Flow: 10~13L/min

Mini Food Grade Pump VP35C

Mini Food Grade Pump VP35C is a food safe material made pump, customer use it in house hold appliance such as coffer maker, juice machine, dispenser etc. Max Head:1.5~3M Max Flow:4.5~7L/min

Mini Cooler Pump VP60D

Mini Cooler Pump VP60D is a kind of small dc quiet water pump, we can use it as a water circulation pump to dissipate heat for CPU, computer or LED light, etc. Head: 2.4M Flow: 6L/min Noise≤ 24dB

Mini booster pump VP60N

Mini booster pump VP60N is 12v or 24V dc water pressure pump, used as a hot water heater pump for solar water heater, electric water heater, instant heater etc. Head: 12M Flow: 21L/min Noise≤ 45dB

Mini High Pressure Water Pump VP60F

Mini high pressure water pump VP60F is a small centrifugal booster Pump. People usually use it in CNC laser cutter machine, water booster system, etc. Max Head: 42M Max Flow: 19L/min

Mini Aquarium Pump VP85A

Built by a bldc motor, mini aquarium pump with characteristic of small size, high efficiency, lower price. It popular in the home fish tank, aquarium market. Max Head: 3.5~5.5M Max Flow: 133~200L/min

Small Motor Pump (View All 10 Models)

Small Motor Pump is a 5V, 12V,24V dc motor pump, they can use for applications such as water heater, water cooling, water circulation, water booster etc. Max Head:≤13M Max Flow:≤1400L/H

Electric Water Pump Car VP90A

Electric water pump car VP90A is key component in automobile cooling system for dissipating heat for car engine, new energy vehicles, hybrid buses, race car etc. Max Head:25M Max Flow:10800L/H

Small Battery Powered Water Pump

Small Battery Powered Water Pump is built by a 5V, 6V, 12V dc motor, People use it in solar fountain, cat water fountain , tabletop crafts, medical equipment etc. Head Range≤1~42M Flow Range:2~40L/min

Mini booster pump VP60N

Small solar water pump driven by a solar panel, widely used in solar water heater, solar farm irrigation, solar fountain, agricultural spray, field water intake etc. Head Range≤2~42M Flow Range:2~43L/min

Want to learn more?

Table of Contents

Small Water Pump Manufacturer

VOVYO Technology Co., Ltd is a small water pump manufacturer from China located in Dongguan city. We Specialized in developing and manufacturing mini water pump, automotive electric water pump and other dc pumps. After years of hard work, VOVYO developed VP25, VP30, VP35, VP40, VP50, VP60, VP62, VP80, VP90 series dc water pumps. Most of them are driven by a 5v, 6v, 12v , 24v or 48V brushless dc motor. Widely used in various application like pet fountain, fish tank, solar irrigation, various water heaters, water circulation system, coffee maker, hot water mattress, car engine cooling or battery management system cooling etc. Moreover, our mini water pump has many advantages such as long work life span, low work noise, safety, low price etc.

VOVYO brand mini water pumps not only popular in China market, but also popular in overseas markets. Such as USA, India, Japan, UK, Germany, Spain, Australia, Canada, South Korea, Brazil, France, South Africa, Italy, etc.

How Does a Mini Water Pump Work?

Common mini water pumps include mini centrifugal pumps, mini self-priming pumps, micro diaphragm pumps, micro gear pumps, etc. What are their working principles? The following is a detailed explanation:

1. Mini Centrifugal Pump

Liquid fills the pump casing when the mini centrifugal pump working, the impeller rotates quickly, and the blades prompt the water to rotate quickly. Rotating water flies away from the impeller under the action of centrifugal force. While the central part of the impeller form a vacuum area, after the water in the pump is thrown out. Water in the water source is pressed into the inlet pipe through the pipe network under the action of atmospheric pressure (or water pressure). In such continuous cycles, realize the continuous water pumping.

2. Mini Self-priming Pump

For ordinary centrifugal pumps, if the suction liquid level is below the impeller, fill the pump with water before starting. Which is very inconvenient. In order to store water in the pump, need install a bottom valve at the inlet of the suction pipe. Lead to the bottom valve causes a great hydraulic loss when the pump working.

Mini self-priming pump is kind of centrifugal pump which does not need to be filled with water into the pump chamber before starting (the first time after installation, it still needs to be filled with water). Or does not need to be filled with water in the suction pipe. After a short period of operation, relying on the centrifugal force of the pump itself, it can automatically pump water up.

3. Mini Diaphragm Pump

Mini diaphragm pump working principle is very simple. Its pump motor drives the eccentric wheel and the connecting rod to oscillate. Thereby driving the reciprocating movement of the diaphragm, forming a complete pumping movement with the valve plate of the air inlet and outlet. When the pneumatic diaphragm pump working, in order to prevent the movable column from directly contacting the corrosive material and liquid. It should separate the cylinder cavity and the liquid material by a diaphragm. Which is essentially the principle of a reciprocating pump too.

4. Mini Gear Pump

When the teeth of the two gears of the gear pump are separated from each other. It form a low pressure, suck in the liquid, and sent to the other side by the shell wall. While the two gears on the other side close together, it form a high pressure to discharge the liquid.

Mini gear pump has the characteristics of simple and compact structure, small size, light weight, good manufacture ability, low price, strong self-priming, insensitive to oil pollution, large speed range, resistance to shock loads, easy maintenance, and reliable work etc.

What Types of Mini Water Pump Are There?

There are many types of mini water pump, also many classification methods.

People divide miniature water pump into valve pumps and valveless pumps, according to whether there are valve parts in the pump; According to whether there are moving parts in the pump, the ones with moving parts are called mechanical Pumps and others are collectively referred to as non-mechanical pumps. Moreover mechanical micro pumps occupy a dominant position; According to the fluid movement mode in the pump, divide them into reciprocating pumps and peristaltic pumps.

According to the braking mode, divide them into electrostatic pump, magnetic pump, piezoelectric pump, pneumatic pumps, thermally driven bubble pumps, liquid power pump, thermal brake bimetallic pump, shape memory alloy pumps, etc. According to the voltage, divide it into AC and DC. Such as mini ac water pump and mini dc water pump; According to different drive motor, divide them into brush and brushless, such as brush pump and brushless pump.

Here, introduce miniature water pump in the form of drive motor.

1. Mini AC Water Pump

The commutation of the mini ac water pump is changed by 50HZ frequency of the mains electricity, its commutation speed is very low. There are no electronic components in the ac water pump, so it can withstand high temperatures. The volume and power of the AC water pump with the same water head are 5-10 times of brushless DC water pump. Advantages: low price, more manufacturers can supply it.

2. Mini DC Water Pump

When the mini dc water pump is working, the coil and commutator rotate, and the magnet and carbon brushes do not rotate. The alternating current direction of the coil is completed by the commutator and brushes that rotate with the motor. Advantages: Price low.

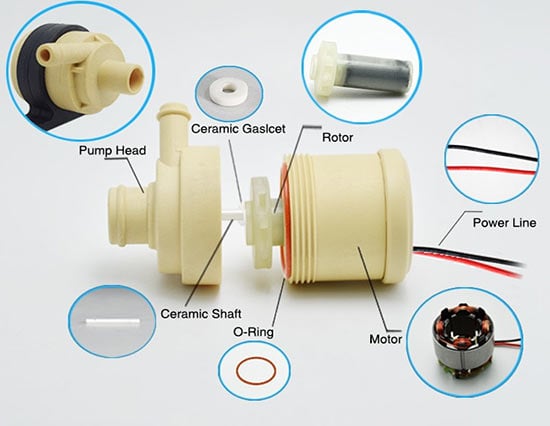

3. Mini Brushless DC Water Pump

Mini brushless DC water pump motor is a water pump composed of a brushless DC motor and an impeller. Advantages: The brushless DC pump motor has been standardized and mass-produced by specialized manufacture. With relatively low cost and high efficiency.

4. Mini DC Magnetic Water Pump

Mini magnetic water pump adopts electronic component commutation, without carbon brush commutation, and adopts high-performance wear-resistant ceramic shaft and ceramic sleeve. The sleeve is integrated with the magnet through injection molding. Avoid wear, so the life of the DC magnetic pump is greatly enhanced. Advantages: high efficiency, long life, low noise up to 35dB or less, can be used for hot water circulation.

What Are the Uses of Mini Water Pump?

A mini water pump can be widely used for computer water cooling system, solar fountain, desktop fountain, handicrafts, coffee machine, water dispenser, tea brewer, wine pourer, soilless culture, shower, bidet, tooth cleaner, water heater plus Pressure, plumbing mattress, hot water circulation, swimming pool water circulation filtration, foot washing surf massage tub, surf massage bathtub, car cooling circulation system, fueler, humidifier, air conditioner, washing machine, medical equipment, cooling system, bathroom products, etc.

Benefit of Miniature Water Pump

Miniature water pump is powered by a dc or ac power supply, solar dc/ac power supply, or dc battery power supply,

so, it is a very attractive choice for people to apply them in their products or application. Compared with traditional fluid pumps, micro water pumps are an order of magnitude smaller in volume while providing the same flow rate. Not only that, the miniature water pump also has the advantages of portable, small in flow, light in weight, fast in response, high in efficiency, low in price, low in noise, high in control accuracy, long life and high reliability, quiet etc.

What to Consider when Purchasing a Mini Water Pump?

There are many types of miniature water pumps. It Including mini submersible pump, food grade water pump, high pressure water pump, 12V water pump, self-priming pump, mini circulation water pump, etc. When choosing a pump, what criteria should be used to select the model that is most suitable for your application? You can consider the purchase from several major points such as working performance, use, whether it needs self-priming, whether the pump is put in the water, medium working conditions, and cost etc:

1. Pump Performance

Select a pump with type and performance meet the requirements of process parameters. Such as application flow, head, pressure, temperature, etc. The most important thing is to determine pump’s voltage, max water head, and how much water flow should be. When it work at a certain water head.

2. Working Medium

Mini water pump must met the requirements of medium characteristics. For pumps that transport flammable, explosive, toxic, reliable shaft seals or non-leakage pumps, such as magnetic drive pumps are required. For pumps that transport corrosive media, the convection parts are required to be made of corrosion-resistant materials. Such as fluorine plastics. For pumps that transport solid particles, the convection parts are required to be made of wear-resistant materials. If necessary, the shaft seal should be flushed with clean liquid.

3. Mechanical Performance

The mechanical aspect requires high reliability, low noise and low vibration.

4. Cost and Supplier Audit

Calculate the pump purchase cost correctly. Audit the mini water pump manufacturer. Require its equipment be of good quality, good after-sales service, and timely supply of spare parts etc.

How to Choose a Mini Water Pump?

At present, there are many types of mini water pumps in the market with different models. How to choose a water pump which is more better for applying it in their application or product, many users are not clear. Here is how to choose a miniature water pump:

1. Water Flow

User should consider the water demand for garden planting, breeding, processing and living, the use of water source conditions, or the circulating water flow required by the water circulation equipment. If the water source is sufficient or the circulation water volume is large, the flow rate of the pump should be determined according to the maximum water demand. Selected pump water flow should be basically consistent with the water demand and water source conditions or the water flow required by the equipment.

2. Water Head

Water pump head should be larger than the actual delivery height. In general, the head of the selected water pump should be 15%~20% larger than the required head for actual application. For example, if the actual output height is 20 meters, you should choose a pump with a water head of 23~24 meters. Otherwise, the water pump is prone to fail to pumping water.

3. Reasonably Choose the Capacity of the Pump

Users should choose the pump according to the amount of water pumping per hour that they needed, the total lift and the size of the suction. Choose a pump with large flow, if the water head needs not to be high. If the head is required high, choose a pump with a small flow and a high head. If require pump with high head and large flow, choose a pump larger than 750 watts. For watering slopes and fruit trees, use a 35-meter high-lift mini self priming pump or a clean water pump.

4. Power Supply

For AC power supply, the motor voltage of the three-phase power supply is 380V. The motor voltage of the single-phase power supply is 220V. The general household lighting power supply is 220V, so it is more economical and convenient to buy a mini water pump with 220V power supply. For DC power supply, generally choose 12V, 24V, 48V DC power supply, or battery supply or solar dc power supply.

5. Installation Compatibility

When select a mini submersible pump, you should pay attention to the maximum outer diameter of the pump. It should be smaller than the inner diameter of the well bore. Otherwise it cannot be installed in the well. When choose WXB series miniature pump, you should consider the assembly form of the pump and the well (direct counterpart pumping, original pipeline matching pumping, and hand pump matching pumping, etc.).

6. Test the Pump

After confirming buy a certain type pump, you should test the machine first and listen carefully to the sound of the machine. Any water pump with low machine sound, no noise, no scratching or collision sound is normal.

How to Install a Mini Water Pump?

How to install the micro water pump depends on which type of water pump you choose. Different types of water pumps have different installation methods.

1. High Vibration Water Pump Installation

For example, a micro water pump with high vibration, small flow, and medium flow pump usually has four mounting feet on the lower part of the pump body, which can be fixed with self-tapping screws to reduce vibration.

2. Low Vibration Water Pump Installation

No need to take special installation method for a miniature water pump that with very small noise and vibration. That’s because of even if the pump is laid flat and does not need to be fixed, the pump can still work normally.

3. Submersible Water Pump Installation

Mini Submersible pump series can work directly in the water. For example, if the weight of the micro submersible pump is relatively large.The balance can be well maintained according to the weight of the pump. So there is no need to add other fixing methods. Nevertheless, the medium-flow submersible pump series generally come with a fixed card seat design, which is convenient for bottom or side installation.

4. Water and Gas Dual-purpose Pump Installation

This type of mini water pump can be installed in any direction. The four shock-absorbing feet hidden at the bottom of the pump body can be rotated out (such as turning 180 degrees parallel to the suction port), and screwed in with self-tapping screws for installation.

How to Use a Mini Water Pump?

Correctly mastering the use method of mini water pumps is an important factor in extending the life span of the pump and reducing economic losses. So how to use a micro water pump? People can use the following methods:

Pre-Operational Check

Before using a small water pump motor that has not been used for a long time. You should check whether the insulation resistance between the windings and the winding to the ground (Generally should not be greater than 1MΩ) is normal. Use it only after the inspection result is normal.

Before use, carefully check whether the bolts are loose, whether the cable plug is damaged or broken. Whether the impeller is stuck or rubbed, and whether the impeller rotates flexibly and without noise.

Check whether the motor wiring and steering are correct. Before starting the mini water pump motor, check the direction of rotation of the electric pump. It should be consistent with the direction indicated by the arrow on the electric pump.The single-phase motor nameplate is marked with a wiring diagram, connect the wiring according to the “forward rotation” connection method.

For mini ac water pump, you should connect the cable to the three-phase plug. Furthermore there must be a grounding wire. For mini dc water pump, the power cable should be connected to a 12v or 24V dc power supply.

Do not fill the water pump with water before wiring, and carry out the connection test under no load. Run the motor with load only after the rotation direction is correct.

Fix the motor body on the machine base horizontally. Install the water inlet pipe to prevent air leakage, the water outlet pipe prevent from leaking. Add an additional support frame, when the pipeline is heavy. Vertically install a bottom valve in the water. Its depth from the water surface should not be less than 300mm to prevent air from entering the pipeline and affecting water suction.

Main Operation Points of Start-up and Shutdown

1. Don’t start and stop the pump motor too frequently. Because the current is much larger when the motor starts than during normal operation. So as to avoid overheating of the motor, affecting the winding insulation performance or even burning the motor.

2. When the suction pipe is equipped with a bottom valve. You can directly add water from the outlet of the water pump until full fill the pump chamber with water. Then connect the water pipe to start closing and starting. When Shutdown the motor, simply pull the switch and cut off the power supply.

3. Fill the pump cavity with water in advance before starting the water pump, if the water pump with no self-priming function. Or arrange the water inlet pipe of the water pump below the liquid surface of the water source. And submerge use a water pump which with submersible function. So as to prevent the water pump without self-priming function from burning its pump motor. Due to the temperature of the motor will rise caused by the dry operation of the pump.

4. Fill the pump with water first. Loosen the bleed screw plug on the upper part of the pump body to remove air. Then start the pump.

Precautions for Using Micro Water Pump

1. Mini water pumps cannot pump water that contains a lot of sand, soil, and debris. Especially water pumps with mechanical seals to avoid early wear and damage of seals. Use a sewage pump when pumping water with a lot of impurities.

2. Do not continuously run the motor exceed more than 2 minutes, when there is no water in the pump chamber. So as to avoid damaging the seals, burning out the motor.

3. Within 3 seconds of turning on the power, if the motor does not run or the speed is low. You should cut off the power immediately, shutdown the motor for inspection and troubleshooting to avoid burning the motor. Do not start the mini water pump motor continuously for more than 6 times per hour. Do not idle run the motor for more than 1 minute, if the water pump without idling protection function.

4. During normal operation, the temperature rise of the motor bearing should not exceed 75 ℃. And the voltage fluctuation should not exceed ±5% of the rated value. For ac water pump, if the pump shaft seal leaks, no more than 60 drops per minute allowed. If too much, replace the seal. For dc water pump, if the pump seal-ring leaks, replace the seal immediately.

5. When the install water pump with the machine down. It is necessary to prevent the motor from being damp and water entering the motor junction box. So as to avoid burning out the motor.

6. When use a high-lift pump for low-lift operations, the pump motor is easily overloaded and heats up. In severe cases, it will burn the motor. For an emergency use, it should install a gate valve on the outlet pipe. It can adjust the amount of water to reduce the flow and prevent the motor from overloading.

7. It is strictly forbidden to wash hands and things around the electric pump and at the water outlet. So as to prevent electric shock and casualties caused by the leakage of the water pump.

8. Unscrew the water drain plug to drain the accumulated water in the pump. So as to prevent rust and cracking, if the pump is not in use temporarily. For long-term shutdown, remove the main parts of the pump for cleaning, oiled, and properly stored. After assembly, the gap between the end face of the impeller and the end face of the pump body should be within 0.3~0.5mm.

What Are the Common Faults of Mini Water Pump and How to Repair?

As mini water pump body is small and light, it is loved by the majority of users and is widely used in many industries. However, some users feedback that the miniature pump often fails during use. The causes and repair methods of common failures are now introduced as follows:

1. Pump Cannot Be Started Normally

Replace the fuse, repair the broken wire or repair the poor contact. If the circuit breaks due to power failure. Repair or replace it, if the stator winding is damaged or the switch contact is poor.

2. Pump Shaft Does Not Rotate

Remove the blockage, if the pump shaft is blocked. Repair or replace them, if the pump shaft and bearings are worn. Adjust the gap, if the impeller collides with adjacent parts.

3. No Water Flow Out from The Pump

Insufficient water diversion, check and repair the bottom valve to prevent water leakage. Or add sufficient water diversion. Tighten the fasteners or replace the leaking parts, if the water inlet pipe leaks. Adjust the motor line, if the impeller rotates incorrectly. The suction stroke is too high, reduce the suction stroke. Replace the impeller, if the impeller is damaged. Remove the blockage, if the bottom valve or pipe is blocked.

4. Insufficient Flow

Reduce the water head, if it is too high. Remove the blockage, if the water pump is blocked in the pipeline. Replace the impeller, if the impeller port is worn or damaged. Repair the bottom valve and make it fully open, if the bottom valve is stuck and cannot be fully opened.

5. Excessive Power Consumption

Straight or replace the pump shaft, if it is bent. Remove the pump and clean it, if there is a blockage in the pump that jams the impeller. Eliminate the friction, if the rotating part has friction.

6. Pump Vibration Noise

Tighten it, if fasteners are loose. Repair it, if pump shafts are bent. Replace it, if bearings or impellers are worn.

7. Pump Motor Overheated

Adjust the voltage, if the voltage is too low. Repair or replace them, if the centrifugal switch contacts are glued or damaged. Increase the wire number, if the wiring is too thin.So as to avoid overheating and burning the mini water pump.

PRODUCT CATEGORY

FEATURED PRODUCTS

| Rated Voltage | 24V |

| Max Head | 24Meters, 25Meters |

| Max Flow | 100L/Min, 110L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 183x103x240mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 45 Meters |

| Max Flow | 100L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 175x100x170mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 18M |

| Max Flow | 280L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 188.1x100x176.9mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 13.5V, 24V |

| Max Head | 14M |

| Max Flow | 55L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 131x112x80mm |

| Noise | ~48dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 220V |

| Max Head | 38M, 48M |

| Max Flow | 100L/Min,100L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 223.4×126.0x178.0mm |

| Noise | ~50dB |

| Liquid Temperature | -30~70 Celsius |

| Rated Voltage | 6V, 12V |

| Max Head | 1.5 Meters, 3 Meters |

| Max Flow | 2.5L/Min, 4L/Min |

| Inlet Diameter | Φ8mm |

| Outlet Diameter | Φ8mm |

| Dimensions | 53.5x40x34mm |

| Noise | ~30dB |

| Liquid Temperature | -25~50 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ18mm |

| Outlet Diameter | Φ9.8mm |

| Dimensions | 82.45×48.0x67.6mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 3M, 8M |

| Max Flow | 8L/Min, 13L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 82.3x102x46.4mm |

| Noise | ~40dB |

| Liquid Temperature | -40~110 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 83.4x48x69.7mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 8M, 15M |

| Max Flow | 20L/Min, 25L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 96.9x73x84.3mm |

| Noise | ~40dB |

| Liquid Temperature | -20~100 Celsius |

| Rated Voltage | 12V, 24V,24V,24V |

| Max Head | 11M, 20M, 25M, 32M |

| Max Flow | 20L/Min, 24L/Min, 25L/Min, 26L/Min |

| Inlet Diameter | Φ20.3mm |

| Outlet Diameter | Φ11.3mm |

| Dimensions | 90.9x60x85.85mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

FEATURES CATEGORY

SUPPORT & BLOG

Get Product Catalog

16.5Mb PDF File, Covers 200+ Models Products.